摘 要

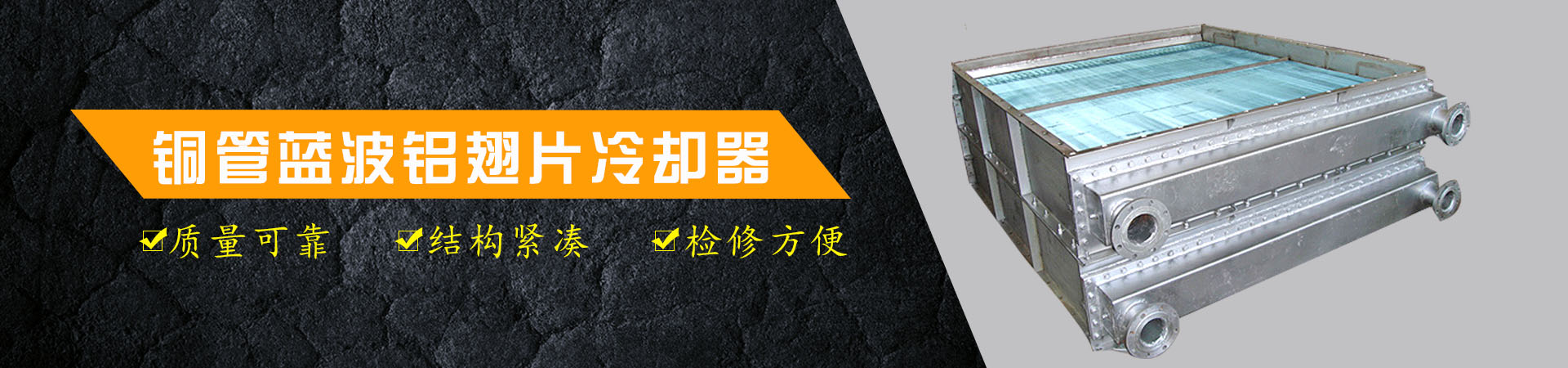

隨著我國空調、制冷業的發展,對翅片管的需求量日益增加。作為翅片散熱管生產的專用設備,翅片散熱管繞制機僅靠進口已經不能適應市場競爭的要求。因此有必要借鑒國內、外繞制機的**技術設計出一種全新的自動繞制機,以適應現在市場的需求。

本文從特殊暖氣管繞制機的功能要求出發,在查閱大量有關國內、外繞制機文獻的基礎上,提出了自動繞制機的總體設計方案,確定了該繞制機的繞制原理、加工工藝過程及總體布置等。

課題來源于哈爾濱熱風機制造廠和哈爾濱理工大學聯合研制開發的合作項目。本設計擬解決原有傳統的半機械、半手工的繞制方式,提高產品質量的穩定性,增加翅片散熱管的繞制品種和規格,降低了操作者的勞動強度,實現了產品螺距的無級調節,并可實現程序管理、參數預設置、自動和手動等功能。能夠有效地提高企業的生產效率和自動化程度,提高企業在市場上的競爭力。

關鍵詞 翅片散熱管;繞制機;電動機;軸承。

Abstract

Along with development of the air-conditions and refrigeration industry, the requirement for fin tube is increasing. As special product equipment of aliform radiator pipe, it can’t adapt the requirement of market competition only by importation. So it is necessary to use advanced technique of demestic and oversea for reference and design a new automatism curling machine to adapting the requirement of market.

This paper is Setting out from function request of special caliduct curling machine, After refer to large numbers of books and related literature of curling machine, the design of automatism curling machine is put forward, and its curling principle, technics process and disposal are confirmed.

The task roots in the cooperate exploitation item between Harbin sirocco machine produce factory and Harbin university of science and technology. This design will resolve the curling problem of half machining and half handworking, advance the stability of product quality, and increase curling variety and specification of fin radiators, depress labor intension of manipulator, and realize function of stepless adjusting to product pitch, program managing, parameter early-setting, automatism or handworking and so on. It can advance enterprise production and automatization, and enhance enterprise competition on the market.

Keywords radiator pipe aliform ; curling machine

目錄

摘要 I

II

第1章 緒 論 1

1.1 課題背景 1

1.2 國內外研究現狀 2

1.2.1 國內研究現狀 2

1.2.2 國外研究現狀 3

1.3 研究的目的和意義 4

1.4 本文研究的內容 4

第2章 總體設計 6

2.1 設計要求 6

2.2 繞制原理 8

2.3 工藝流程 9

2.4 總體布置 10

2.4.1 基本要求 10

2.4.2 布置形式及選擇 11

2.5 運動計算 13

2.6 動力計